Recently we had a client make the move from printing in-house to outsourcing with us. After their first order, we were asked the question as to why the cards we produce look so much prettier than their old, in-house ID badges. Both were printed on similar PVC stock, and the printer that they had used in-house had been “fairly expensive”.

Their fairly expensive (defunct) printer was a “Direct to Card” (DTC) printer. This means that it printed, well, directly to the card. This technology might seem to make the most sense. After all, our paper printers print, well, directly to paper. When printing directly to PVC, however, the color rendering is not very sharp. Small imperfections in the plastic prevent a complete coating of the material, and the plastic itself is resistant to the dye. Additionally, DTC does not offer true edge-to-edge printing—there is always a thin white band at the edge of the card.

So why do so many printers use DTC technology?

To put it simply, it is cheap—our client’s old “fairly expensive” machine would have been “let’s-outsource-to-begin-with expensive” had they gone with a higher-quality alternative to DTC printing.

Ok, so why are InstantCard’s cards so much prettier than DTC printed cards?

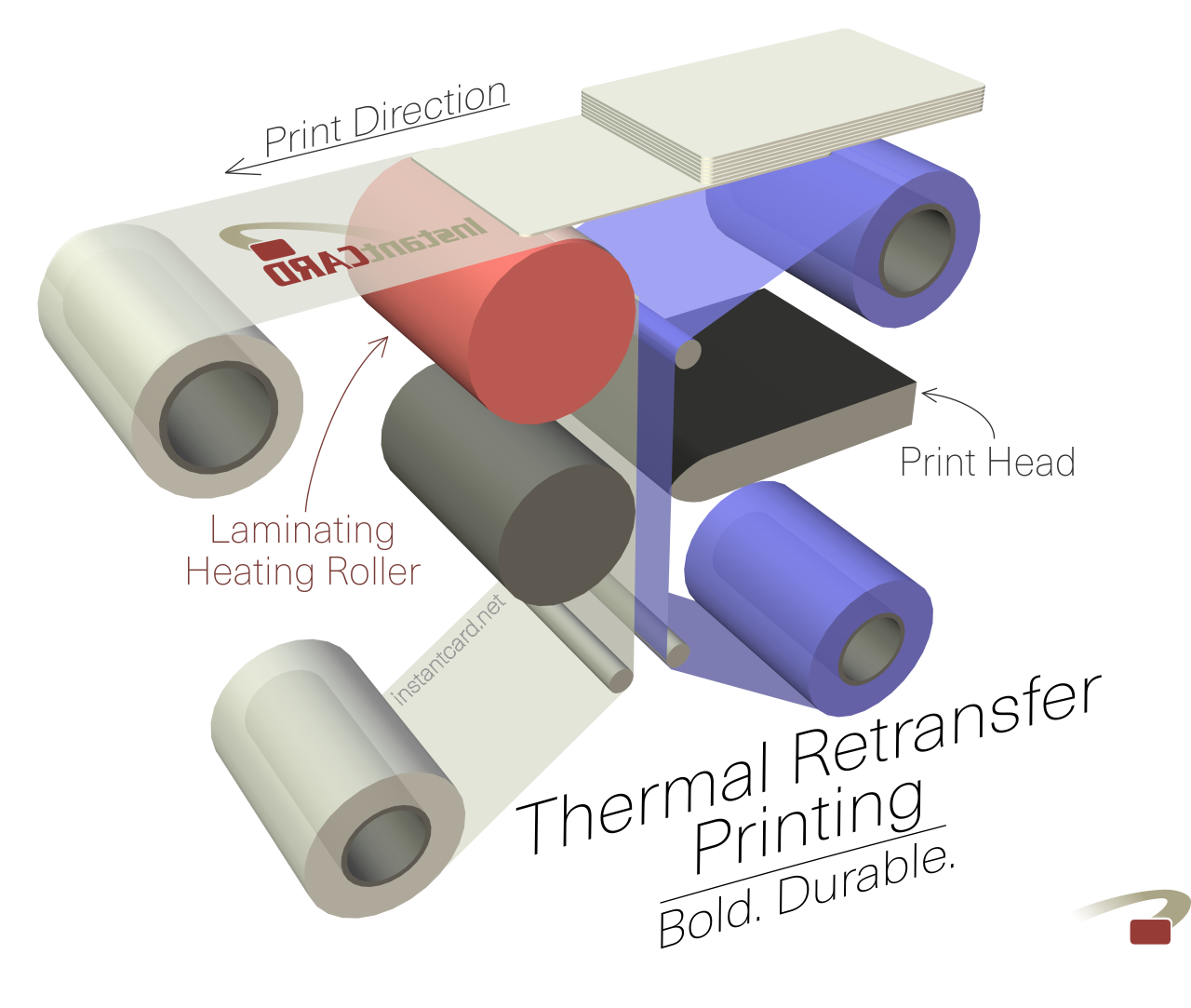

At InstantCard, we use “Thermal Retransfer” (TR) printing. This is, in fact, why our cards look so pretty. TR prints the card image first to a thin film. Then, using heat, the image is affixed to the card itself.

This has several advantages:

1. The color brilliance is based on how well the film takes the dye.

2. The image is more durable (dye scratches off of PVC more easily).

3. We can actually print on cards of varied shape (like prox/RFID cards).

4. We can print to the edge (a little extra image called “bleed” is printed on the film past the edge of the card).

I’ve heard about offset printing. Is that prettier than TR?

You got us—sort of. Offset printing (OP) is of slightly higher caliber than TR. However, such technology may only be implemented where the PVC stock is being produced. Additionally, it does not allow us to print to either prox or RFID cards (or any sort of textured cards). At InstantCard we pride ourselves with offering the best and latest in technology options for your ID badge program. TR technology best facilitates this (while still looking amazing).

In the end, we offer you cards of amazing quality with no limitations on technology. If you’re still not sure, feel free to request a sample card. You’ll see why our client asked how our cards are so “pretty.”

Update:

After writing this post, quite a few people have contacted us asking to see actual samples of our cards. So, I decided it best to just add our free sample request form directly to the post. I hope this helps if you want to see for yourself. Of course you’re still welcome to contact us if you have any other questions!